What is the Process, and Benefits of 17.4 PH Stainless Steel?

Type 17-4 PH stainless steel is the most widely used of all precipitation-hardening stainless steel. Its advantageous mix of attributes offers designers the chance to increase the durability of their goods while streamlining fabrication and frequently lowering costs. At temperatures up to 316°C (600°F), Type 17-4 PH, a martensitic precipitation-hardening stainless steel, offers an exceptional combination of high strength, superior corrosion resistance, and good mechanical qualities.

Process of 17.PH Stainless Steel

- Heat Treatment

- Cold Forming

- Hot Forming

- Cutting

- Welding

Heat Treatment

Alloy 17-4PH is provided in the solution-annealed condition (Condition A). Mechanical properties may be altered by subsequent age-hardening treatments. These aging treatments are referred to as Conditions H900, H1025, H1075, H1150, H1150M, and H1150D.

Hot Forming

At 1742-2192°F (950-1200°C), heat uniformly. Hot forming must be followed by a thorough solution anneal, cooling to below 76°F (25°C), and aging at the necessary temperature. The intended mechanical qualities should influence the post-forming heat treatment.

Cold Forming

Alloy 17-4PH has limited cold-forming properties. Cold forming can only be undertaken on plates in fully annealed condition. Stress corrosion resistance is enhanced by re-aging at the precipitation hardening temperature after cold working.

Cutting

Plasma cutting and other thermal cutting methods ought to be avoided. The band saw, abrasive water jet, shearing, and machining are popular mechanical cutting operations.

Welding

Alloy 17-4PH is easily welded using the majority of common techniques, including SMAW, GTAW, PAW, and GMAW.

Benefits of 17.4PH Stainless Steel

- Depending on the application, it is possible to harden something to adjust its strength and hardness.

- High strength with moderate corrosion resistance

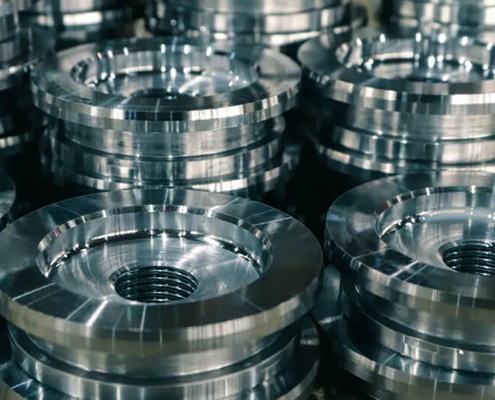

- Can be machined in solution-treated and heat-treated conditions

- Retains its mechanical properties and corrosion resistance up to roughly ~600°F

- Great formability and weldability

- Resists corrosion better than any of the commonly used hardenable (martensitic) stainless steels.

- Superior resistance to corrosive material and high mechanical properties. This allows it to be used in marine environments.

- Can be designed in such a way as to seal radioactive storage.

https://www.besteelalloys.in/wp-content/uploads/2022/12/Nitronic-50-and-60-Suppliers-in-Chennai.jpg

400

500

besteel_login

https://www.besteelalloys.in/wp-content/uploads/2022/10/logo.png

besteel_login2022-12-19 07:23:362022-12-19 07:25:1117.4 PH Suppliers in Chennai

https://www.besteelalloys.in/wp-content/uploads/2022/12/Nitronic-50-and-60-Suppliers-in-Chennai.jpg

400

500

besteel_login

https://www.besteelalloys.in/wp-content/uploads/2022/10/logo.png

besteel_login2022-12-19 07:23:362022-12-19 07:25:1117.4 PH Suppliers in Chennai