Wire Flat Wire Round Wire Special Wire Shapes Square Wire

Custom ShapesForgings

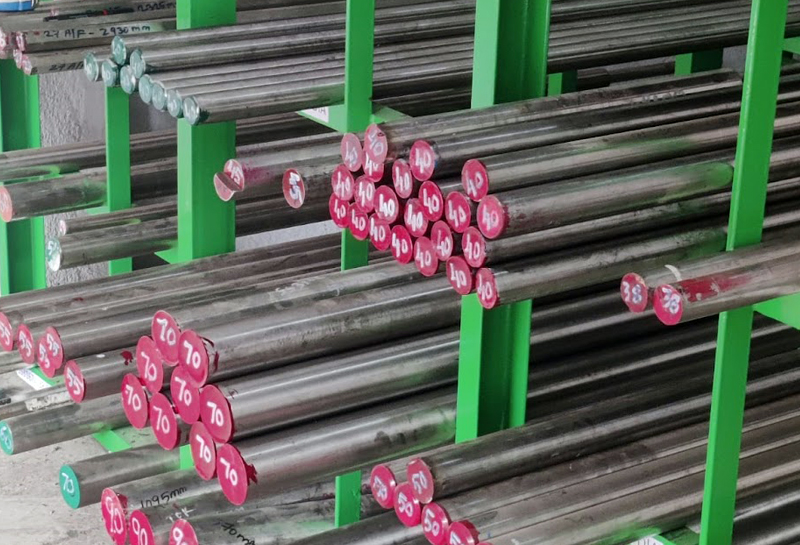

INVENTORY FORMS

Rod, Flats, Square, Hex, Coil, Plate, Sheet, Strip, Foil, Tubes and Wire.17-4 PH sheet sizes: 17-4 PH Sheet SizesCompliance: Metals distributed by Ragavendra Eingineerng.

| HEAT TREATMENT CHART | |||

| Condition | Hardening Temp, | Hardening Time | Type of |

| ± 9 °C (± 15 °F) | (hours) | Cooling | |

| A | Solution Treated at 1038 ± 14 °C (1900 ± 25°F)0.5 hr Oil, | ||

| Solution Treated at 1038 ± 14 °C (1900 ± 25°F)0.5 hr Oil, | |||

| H 900 | 482 °C (900 °F) | 1 | Air |

| H 925 | 496 °C (925 °F) | 4 | Air |

| H 1025 | 552 °C (1025 °F) | 4 | Air |

| H 1075 | 579 °C (1075 °F) | 4 | Air |

| H 1100 | 593 °C (1100 °F) | 4 | Air |

| H 1150 | 621 °C (1150 °F) | 4 | Air |

| H 1150-D | 621 °C (1150 °F) | 4 | Air |

| 621 °C (1150 °F) | Followed by 4 | Air | |

| H 1150-M | 760 °C (1400 °F) | 2 | Air |

| 621 °C (1150 °F) | Followed by 4 | Air | |

15.5 PH

Stainless steels are sometimes referred to as high-alloy steels. These steels exhibit superior corrosion resistance in comparison to other steels due to their higher chromium content. Stainless steels are classified into three groups according to their crystalline structure. These are the martensitic, austenitic, and ferritic groups.

Precipitation-hardened steels are a fourth class of stainless steels comprised of martensitic and ferritic steels. Stainless steel grade 15.5 is a precipitation hardenable stainless steel. This steel exhibits excellent resistance to stress and general corrosion cracking, as well as high transverse toughness and strength, all of which are achieved through a single low temperature heat treatment.

| CHEMICAL COMPOSITION – 17.4 PH / 15.5 PH | |||||||

| C | S | P | Mn | Si | Cr | ||

| Max | Max | Max | Max | Max | |||

| 0.07 | 0.010 | 0.04 | 1.00 | 1.00 | 14.00-15.00 | ||

| 0.07 | 0.030 | 0.04 | 1.00 | 1.00 | 15.00-17.00 | ||

| C=CARBON Si=SILICON Mn=MANGANESE P=PHOSPHOROUS S=SULPHUR Cr=CHROMIUM Mo=MOLYBDENUM | |||||||

| Ni=NICKEL N=NITROGEN Zr=ZIRCONIUM Ti=TITANIUM Cb=COBALT Ta=TANTALUM AI=ALUMINIUM | |||||||

| MINIMUM MECHANICAL PROPERTIES | ||||||||

| Property | H 900 | H 925 | H 1025 | H 1075 | H 1100 | H 1150 | H 1150D | H 1150M |

| UTS, | 1310 (190) | 1170 (170) | 1070 (155) | 1000 (145) | 965 (140) | 930 (135) | 860 (125) | 795 (115) |

| MPa (ksi) | ||||||||

| 0.2% YS, | 1170 (170) | 1070 (155) | 1000 (145) | 860 (125) | 795 (115) | 725 (105) | 725 (105) | 520 (75) |

| MPa (ksi) | ||||||||

| Elongation % | 10 | 10 | 12 | 13 | 14 | 16 | 16 | 18 |

| Reduction of | 40 | 44 | 45 | 45 | 45 | 50 | 50 | 55 |

| Area % | ||||||||

| Brinell | 388 | 375 | 331 | 311 | 302 | 277 | 255 | 255 |

| Hardness | ||||||||

| Rockwell | C40 | C38 | C35 | C32 | C31 | C28 | C24 | C24 |

| Hardness | ||||||||

| Impact, Charpy | — | 7 (5) | 20 (15) | 27 (20) | 34 (25) | 41 (30) | 41 (30) | 75 (55) |